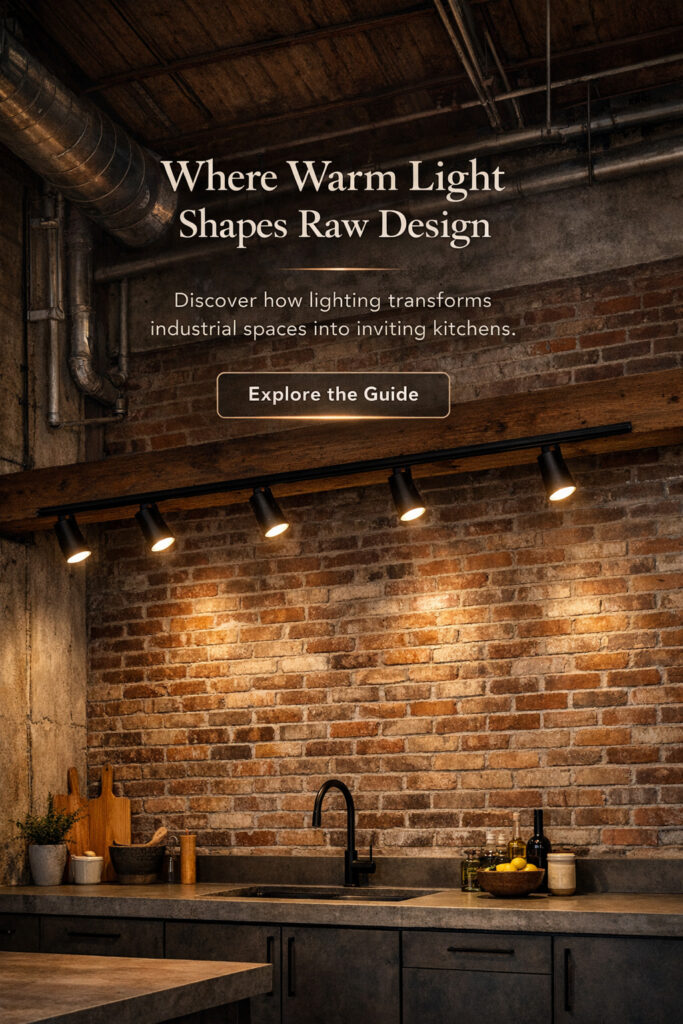

Industrial kitchen lighting is typically defined by exposed materials, visible fittings, and higher contrast between light and dark surfaces. Lighting is often used to highlight textures such as brick, metal, and concrete while supporting everyday kitchen tasks.

This article explores lighting from a style and inspiration perspective. For technical layout, brightness, and placement guidance, see our main kitchen lighting guide.

This guide explains common lighting types, placement strategies, and colour temperature choices used in industrial-style kitchens.

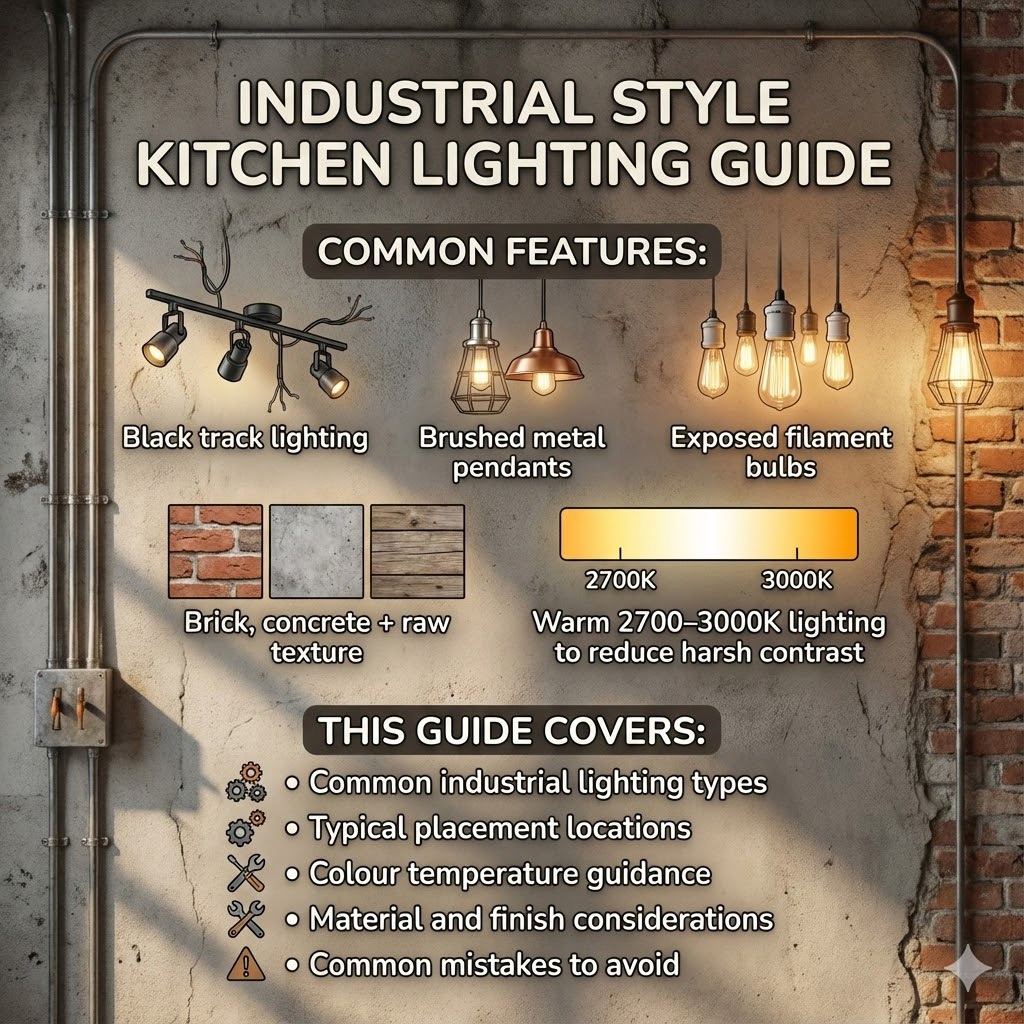

Common features of industrial kitchen lighting include:

- Black track lighting

- Brushed metal pendants

- Exposed filament bulbs

- Brick, concrete + raw texture

- Warm 2700–3000K lighting to reduce harsh contrast

This guide covers:

- Common industrial lighting types

- Typical placement locations

- Colour temperature guidance

- Material and finish considerations

- Common mistakes to avoid

Table of Contents

What Makes Lighting “Industrial”?

Industrial lighting originated in factory and warehouse environments, where fittings were designed primarily for function.

Design features:

- Visible hardware

- Warm exposed bulbs

- Matte black, steel or aged brass

- Linear and geometric shapes

- Influenced by loft and warehouse interiors

- Combination of raw and finished materials

Industrial lighting combines functional fittings with visually prominent materials.

Combining metal finishes with timber elements and warm lighting helps reduce visual contrast.

Common Types of Industrial Kitchen Lighting

Let’s break down the real workhorses of this style.

Track Lighting — Architectural + Adjustable

Industrial kitchens need directional task light.

Track lighting provides directional task lighting in industrial kitchens.

Why it works:

- High contrast shadow play

- Commonly used for awkward layouts

- Easy to reposition

- Perfect for highlighting brick + tile texture

Where to use:

- Long galley kitchens

- Over kitchen islands

- Along exposed-beam ceilings

Metal Pendants — Common Industrial Feature

These often act as focal lighting elements in industrial kitchens.

Best shapes:

- Factory dome pendants

- Warehouse cage pendants

- Long linear bar lights

- Enamel-coated shades

Where they shine:

- Over island seating

- Above dining zones

- In sightline focal areas

Using warm, dimmable bulbs can help reduce glare in the evening.

Exposed Filament Bulbs — Accent Lighting

Tip: Avoid too many exposed bulbs – excessive glare can be uncomfortable.

Best looks:

- Vintage Edison-style

- Spiral or squirrel cage filament

- Thin black or brass lampholders

They work best in:

- Smaller clusters

- Over breakfast bars

- As accent lighting only

Tip: Avoid too many exposed bulbs – excessive glare can be uncomfortable.

Wall Lights — Shadows & Structure

Industrial wall sconces add contrast where cabinetry ends and wall surfaces are exposed.

Typical placements:

- Flanking a brick feature wall

- Next to dining nooks

- Above a coffee station

- Highlighting open shelves

Best styles:

- Metal swing arms

- Pipe-inspired fittings

- Minimal black up-down lights

Under-Cabinet and Plinth Lighting

Industrial kitchens still require balanced lighting.

LED strips are often used to reduce contrast:

- Shadow-free prepping

- Warm edges around cold materials

- Reduced contrast during lower brightness settings

3000K is commonly used to balance warmth and clarity.

More strip lighting help

/guides/led-lighting/

Where to Position Industrial Lighting

Lighting placement in industrial kitchens is typically deliberate and structured.

- Over prep zones

- Directed to textures (brick, tile, plaster)

- Along exposed beams or steel supports

- Above island edges, not centre

- Wall grazing to create shadow definition across textured surfaces

Avoid blasting direct light onto glossy finishes — choose diffused where needed.

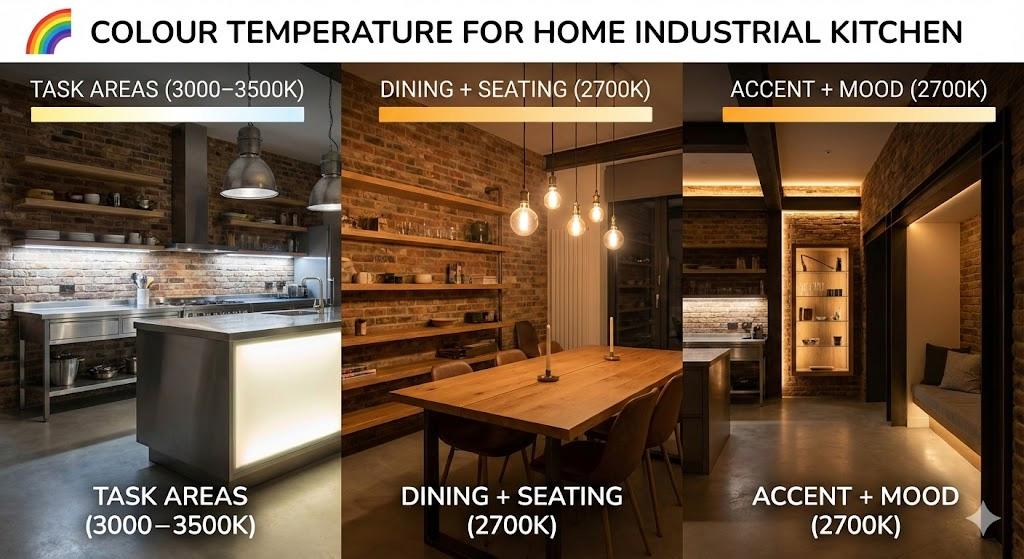

Colour Temperature for Industrial Kitchens

Industrial kitchens typically feature metal finishes and contrast, making warmer colour temperatures commonly used.

| Zone | Best CCT |

|---|---|

| Task areas | 3000–3500K |

| Dining + seating | 2700K |

| Accent + mood | 2700K |

4000K is less commonly used in industrial kitchens due to its cooler appearance.

Full CCT guidance

/guides/colour-temperature/

Materials Commonly Used with Industrial Lighting

These textures are commonly highlighted using warm light:

- Brick

- Concrete + terrazzo

- Rough timber

- Matte black metals

- Frosted or smoked glass

- Handmade ceramics

Example Industrial Lighting Layouts

Small Kitchen

- Single track light

- Warm LED under cabinets

- One feature wall lamp

Medium Kitchen

- 2–3 black pendants over island

- Track lighting to support task depth

- Plinth lighting for softness

Open-Plan Kitchen-Diner

- Track over kitchen zone

- Pendants over dining

- Wall lights to separate spaces

- Warm low lighting in the evening

Industrial style = zoning with contrast.

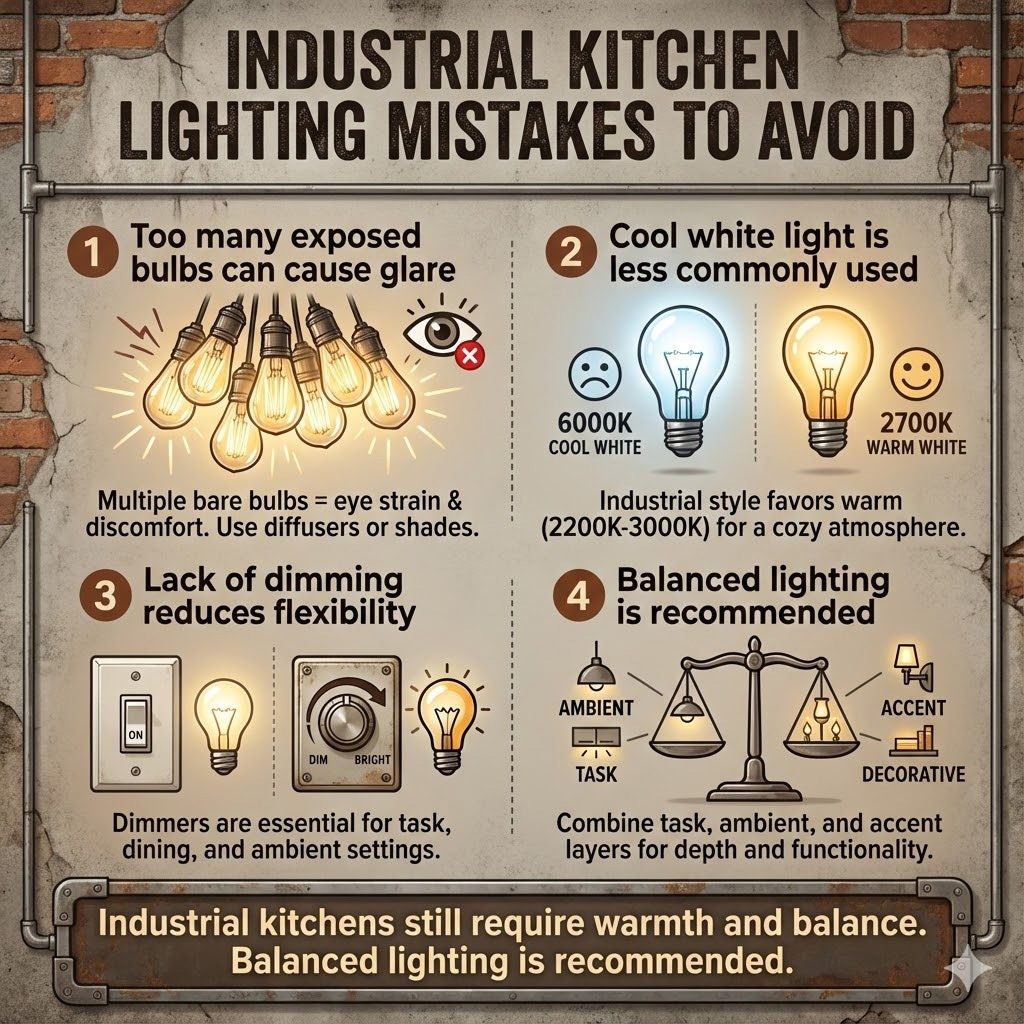

Mistakes to Avoid

- Too many exposed bulbs can cause glare

- Cool white light is less commonly used

- Lack of dimming reduces flexibility

- Balanced lighting is recommended

Industrial kitchens still require warmth and balance.

Balanced lighting is recommended.

Evening Lighting Settings

In the evening, industrial kitchens often rely on reduced brightness and fewer active light sources to limit glare and visual contrast.

Switch to:

- Pendants dimmed low

- Plinth or shelf strips

- Wall lights only

- Reduced glare across metal and stone surfaces

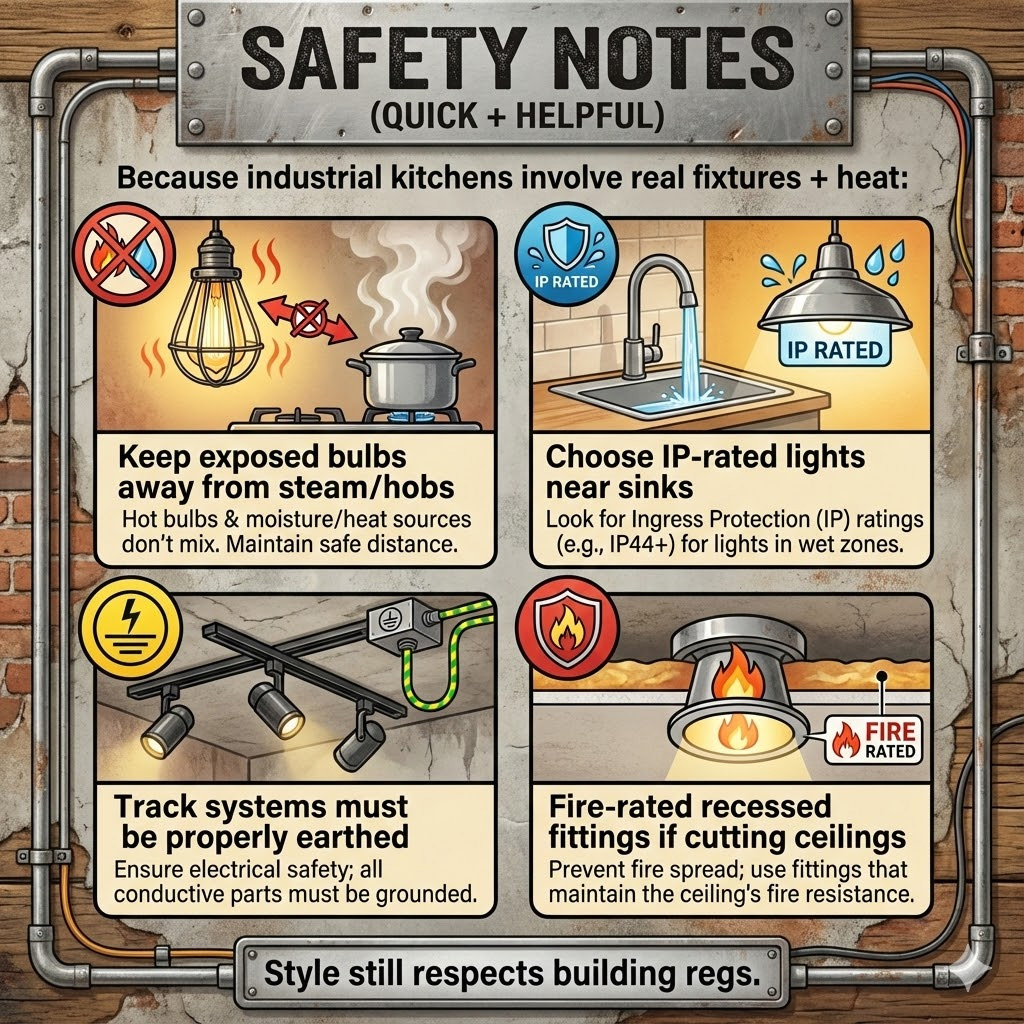

Safety Notes (Quick + Helpful)

Because industrial kitchens involve real fixtures + heat:

- Keep exposed bulbs away from steam/hobs

- Choose IP-rated lights near sinks

- Track systems must be properly earthed

- Fire-rated recessed fittings if cutting ceilings

Style still respects building regs.

FAQ (People Also Ask)

Is industrial lighting good for small kitchens?

Yes – black fixtures add contrast and structure in compact rooms.

Does industrial lighting need exposed brick?

No – concrete, timber or even plain white walls work if contrast is layered.

Should industrial kitchens use warm or cool lighting?

Warm white lighting between 2700–3000K is commonly used.

Do track lights look industrial?

Track lights are often used, particularly in matte black finishes.

Can industrial lighting appear less harsh?

Warm, dimmed lighting can reduce contrast in industrial kitchens.

Conclusion

Industrial kitchen lighting typically balances exposed materials with warm colour temperatures and layered light sources. Using task, ambient, and accent lighting together helps maintain usability while highlighting industrial textures.

Careful placement and dimming allow industrial kitchens to remain practical throughout the day without excessive glare or contrast.

Explore more lighting ideas here:

Some helpful external links for more knowledge:

UK Government Building Regulations (Part P)

NICEIC (UK electrical standards)